Swab sampling is a widely used microbiological monitoring method in the pharmaceutical industry. Its main purpose is to check whether manufacturing areas, equipment, and surfaces are clean and free from harmful microorganisms.

Maintaining a contamination-free environment is critical in pharmaceuticals because even tiny amounts of microbes can affect product safety, quality, and patient health.

What Is Swab Sampling?

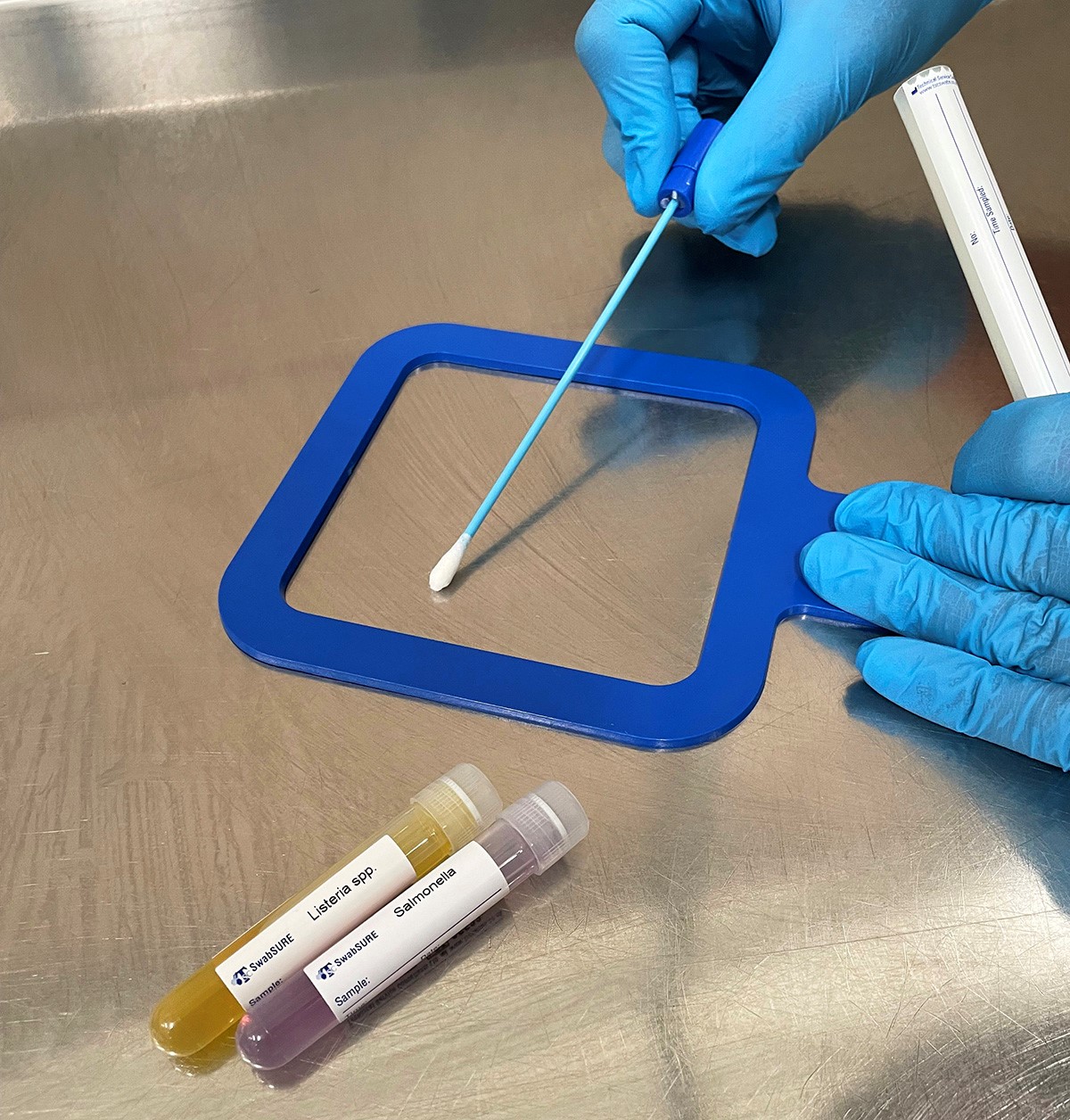

Swab sampling involves using a sterile swab (usually made of cotton, polyester, or foam) to collect microorganisms from a specific surface. The swab is then tested in a laboratory to identify and count any microbes present.

This method is especially useful for hard-to-clean or hard-to-reach areas where other sampling methods may not work well.

Why Is Swab Sampling Important?

Swab sampling plays a key role in:

Preventing contamination of pharmaceutical products

Verifying cleaning and sanitization effectiveness

Meeting regulatory requirements (such as GMP guidelines)

Protecting patient safety

Regulatory agencies expect pharmaceutical companies to routinely monitor their environments, and swab sampling helps demonstrate control over hygiene conditions.

Types of Swab Sampling:

1. Contact Swabbing

– This method involves directly wiping the surface with a moistened swab to collect any residues. It’s commonly used on flat surfaces and equipment where residues might remain after cleaning.

2. Rinse Swabbing:

– In this method, the swab is first moistened with a solvent (e.g., water, alcohol, or a buffer solution) and then used to wipe the surface. This helps in dissolving and collecting soluble residues, particularly useful for detecting substances that might not be easily picked up by dry swabs.

3. Dry Swabbing:

– This approach uses a dry swab to collect samples from surfaces, typically to capture particulates or substances that are not soluble in liquids. It’s less commonly used but effective for specific applications.

4. ATP (Adenosine Triphosphate) Swabbing:

– ATP swabs are used to detect organic matter (including microbial contamination) on surfaces by measuring the level of ATP present. This method provides rapid, on-the-spot results and is often used for routine monitoring of surface cleanliness.

5. TOC (Total Organic Carbon) Swabbing:

– This technique involves using a swab to collect samples for analysis of total organic carbon, which helps determine the amount of organic residue present on the surface. It is particularly useful in cleaning validation processes.

6. Microbiological Swabbing:

– Used to assess microbial contamination on surfaces, this method involves swabbing a surface and then culturing the sample to identify and quantify microorganisms. It’s essential for monitoring the sterility of environments and equipment in aseptic processing.

Advantages of Swab Sampling

-

Can sample small and uneven surfaces

-

Effective for residue and microbial detection

-

Easy to perform with minimal equipment

-

Suitable for validation of cleaning procedures

Limitations of Swab Sampling

-

Results depend heavily on proper technique

-

Not ideal for large surface areas

-

May recover fewer microorganisms compared to some other methods

Because of this, swab sampling is often used alongside other monitoring techniques, such as contact plates or air sampling.